Introduction / summary:

Early integration and validation of ECUs (electronic control units) is key for successful and cost-efficient development of automated vehicles.

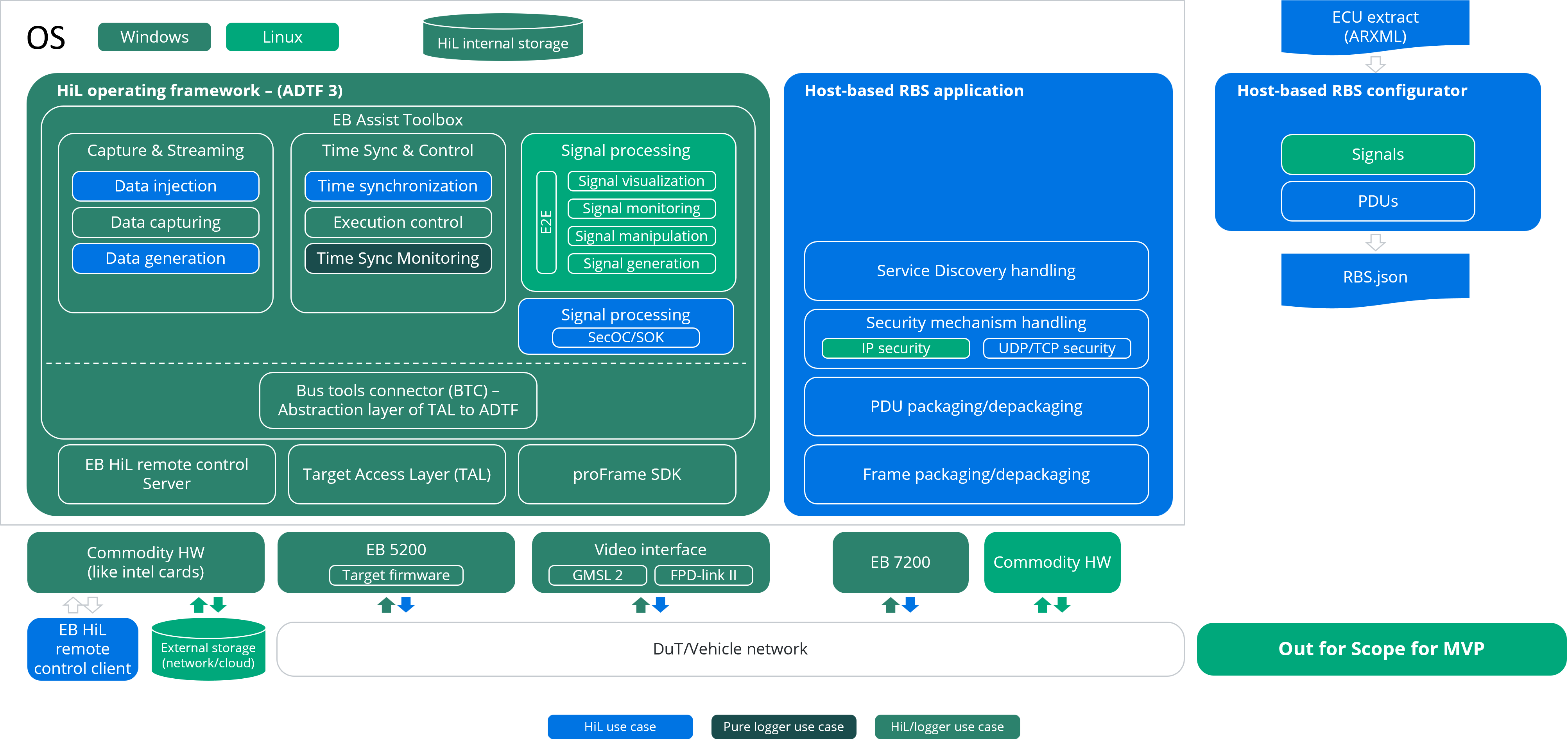

With our data replay and simulation solutions you can test the functions, system integration, and (inter-)communication of ECUs (e. g. ADAS or Infotainment) in a simulated environment under realistic conditions facilitating the difficult and time-extensive process step of in-car-integration and -validation.

Our modular hardware and software solutions have shown their benefits in various projects with OEMs and tier-1s:

From individual test benches supporting software developers up to highly-scaled and performant HiL farms with hundreds of HiLs running 24/7 and generating KPIs for the qualification of ECUs.

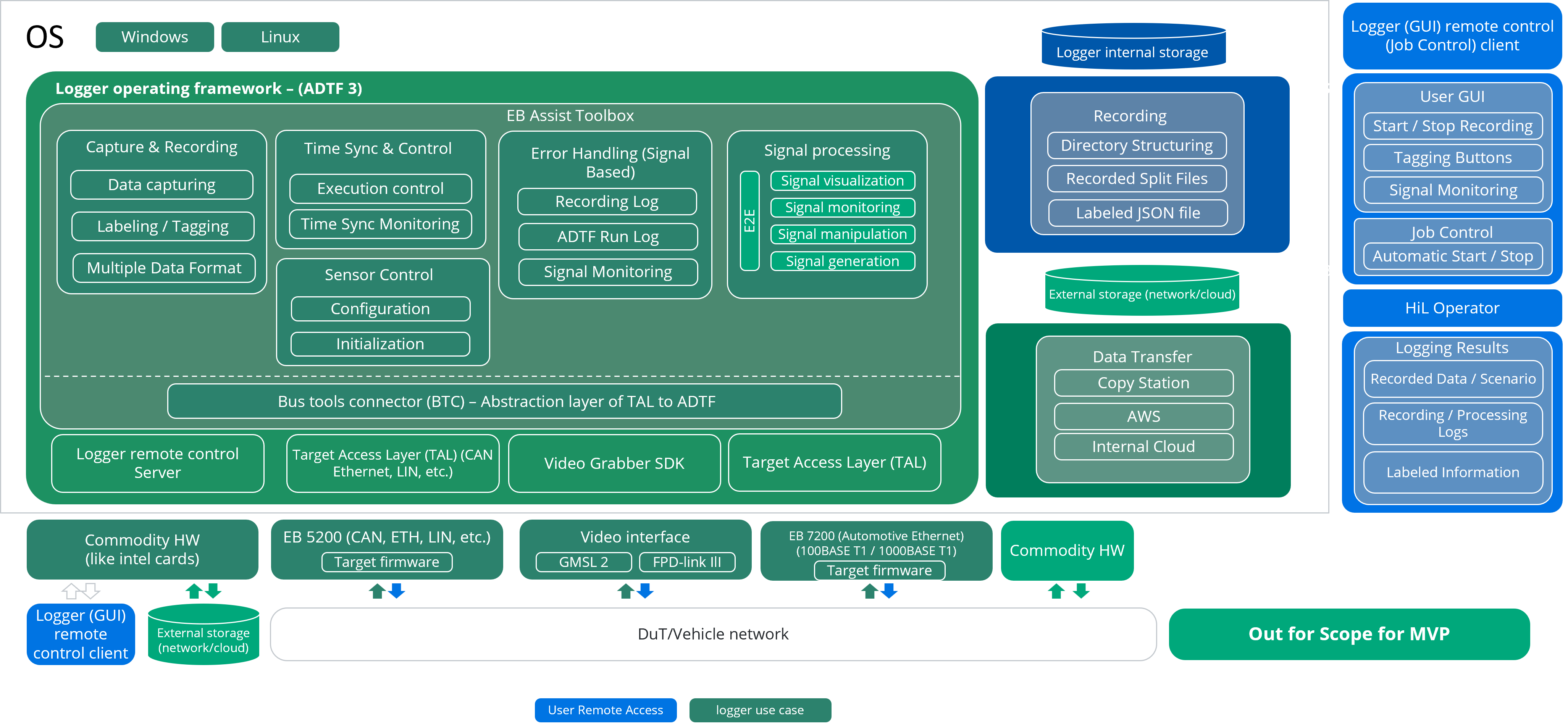

With EB Assist Replay Solution you will be able to accurately replay your vehicle sensor data like video (e.g. with EBX3 card: GMSL2/FPD3/GVIF) or bus communication (e.g. with EBX3 card: 2.5 GBASE-T1, Automotive Ethernet, CAN/CAN-FD, Flexray, DSI3, GPS) in a time synced way.

Improve product quality

Safely test any given situation in a simulated environment and foster quality control. Our solutions are compliant with the latest AUTOSAR version, meeting the highest quality criteria of mass production software. While we currently support up to R20-11, we are continuously working towards integrating the latest version R23-11.

Maximum efficiency

Validate the ECU functionality through processing real driving scene data and shorten the time to market despite more and more complex vehicle network architectures. Profit from high processing power that allows the replay of multiple sensor streams such as camera, LIDAR, or vehicle bus communication.

Minimize in-car integration efforts through off-car reproducibility

Simulated tests are easy to reproduce and allow for the detection of errors already during predevelopment, playing a crucial part in bringing vehicles into mass production. Moreover, implementations and error corrections can be pre-verified prior to (expensive) overall in-car integration.

Ready to use, customizable turnkey solutions

A solution built from interlocking and proven-in-use hardware and software products, ready to use right from the start. Easily customizable with our specific add-ons or your own unique extensions.

High level of safety through error injection and edge case testing

The signal manipulation capabilities of our solutions allow on-the-fly introduction of error cases (e. g. out-of-bounds values) while monitoring the ECU responses with the ability to trigger actions when certain scenarios are detected. This provides important insights into the robustness of the ECU software and its functions.

Customizable Hardware-in-the-loop simulation based on proven in use harware and software products

Key features

- Comprehensive solution that allows for integration of third-party software

- Modeling tools that are based on industry standards

- Replay of video data (e.g. with EBX3 card: GMSL2/FPD3/GVIF) and all relevant vehicle bus communication data (e.g. with EBX3 card: 2.5 GBASE-T1, Automotive Ethernet, CAN/CAN-FD, Flexray, DSI3, GPS) synchronously with nanosecond precision

- Scalable system and processing power that allows replay and processing of multiple sensor streams (e.g. for ADAS/AD, HMI)

- Built with modular, proven-in-use hardware

- “Precision and Correctness report” generated from a HiL-to-HiL hardware setup proofing the high-quality data replay for each data stream and the correlation between each other.

- EB Assist ADTF3 development environment for configuration and extension of existing data replay features including security protocol support (E2E, SecOc, TLS/DTLS)

- EB Assist Control: Orchestrate your HiLs scheduling reprocessing, HiL SW deployment or ECU SW flashing jobs

- Manipulate signals of your input data on-the-fly for error injection and edge case testing

- Visualization of input and output signals of the ECU to support testers in monitoring the test case execution and its result

- Comprehensive driving scene database

- Proven-in-use, host-based rest bus simulation which can be easily configured via JSON files (generated from our RBS Configurator using vehicle system description files (ARXML)

- Support of latest AUTOSAR version

Use cases

- Open-loop and closed-loop HiL (reinjection)

From single-component tests to vehicle network testing to system tests for KPI calculations (e.g. ECU performance tests, object detection ratio and maturity)

Error reproduction and verification of error corrections

Pre-car integration of ECU SW by re-injecting input data (e.g. from test drives) against ECU SW release candidates

Integration into CI/CT/CD tool chain for continuous qualification of the ECU SW using remote control (Assist Control)

Capturing of ECU responses including debug data for either manual post processing or automated test case evaluation (via signal monitoring feature)

Potential integration of customer components inside the HiL (e.g. for visualization or post-processing)

- Rest bus simulation

BroadR-Reach Ethernet

Fully automated HiL system in cluster network (HiL farm)

Data export for KPI calculation

- Automated HiL system in a cluster network

- Data export for calculating KPI

- Recapturing of data

Further information on Elektrobit’s HiL solution and other automated driving solutions